How to Choose Conveyor Rollers

As the leader of your manufacturing company, the survival of your business depends on sales. Your family, your employees, and their families are counting on you to make decisions that will get your products sold and produce a profit. That means you need to regularly compare your current process to industry best practices for reduced cost and time.

As the leader of your manufacturing company, the survival of your business depends on sales. Your family, your employees, and their families are counting on you to make decisions that will get your products sold and produce a profit. That means you need to regularly compare your current process to industry best practices for reduced cost and time.

In this article, we’d like to focus your attention on conveyor rollers. Since there are many designs, sizes, and configurations, here’s a guide on how to make smarter decisions when selecting roller conveyors for your application.

Conveyor Load Type

The first step in choosing the best conveyor rollers for your application is to select based on your load. For example, if your loads include firm, flat bottoms (e.g., skids, totes, cartons, firm bags, drums) you need a conveyor with gravity rollers.

Roller Material: Aluminum, Steel, or Both?

Next, decide on what type of roller material will best suit your application. Industrial rollers are typically made of aluminum or steel. Here is a guide to select what type you need:

- Aluminum Rollers: Choose aluminum rollers for lighter, easier, faster installation.

- Steel Rollers: Choose steel rollers when your application requires more durability.

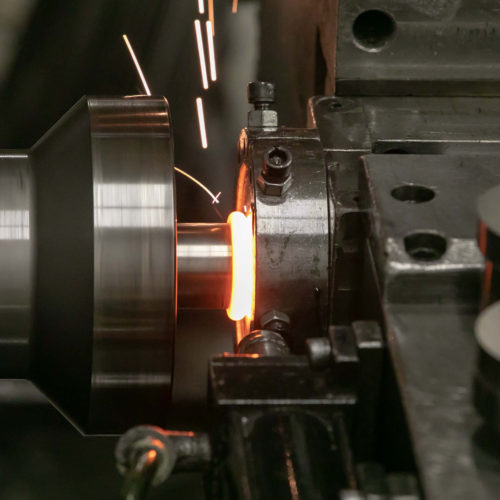

- Both: Choose both if you want lighter aluminum rollers that feature durable steel endcaps by using the unique combination capabilities of inertia friction welding. This also reduces the cost by using less raw materials and only using more expensive materials in required areas.

Conveyor Roller Size

Now you need to know what size rollers to choose. You can determine the size you need by considering load and load conditions.

- Load: If your application features heavy loads, choose larger rollers that meet/exceed the load per roller.

- Loading conditions: If your application features impact loading conditions, choose larger tubing with a heavier gauge.

Load-to-Roller Contact

As a general rule, make sure that at least 3 rollers are always in contact with your load. In order to ensure this, you may need to reduce the spacing in between rollers.

Set Rollers High or Low

Depending on your application, you may need your conveyor rollers set high or low. What is the difference?:

- High Rollers: High settings place the rollers above the conveyor frame to allow for load overhang.

- Low Rollers: Low settings place the rollers below the conveyor frame to allow the frame to act as a guard. For low settings, there should be a 1” clearance on each side of the largest sized load to avoid conveyor errors.

Ready to Get Started?

If reducing manufacturing cost and time with better conveyor rollers is important to you, contact us. During our conversation we can discuss feasibility, potential savings, and if we can provide the best-fit conveyor rollers for your application.

Related Posts

What is Inertia Friction Welding? Inertia friction welding is a solid-state welding process that joins materials by using rotation and friction to generate heat, and lateral force to plastically displace material and fuse the workpieces together. Since its early development,…

There are many types of friction welding methods that can optimize your manufacturing process. In this article, we will review several different types. Understanding these different types will help you decide which can increase precision and reduce total cost and…

Manufacturing problems can hinder profitability for industrial printer and material handling OEMs. It is critical to be aware of these problems in your own manufacturing operations before they cost you your business. So what are the top manufacturing issues and…