How Innovation Leads to Growth: A Look at Industrial Roller Manufacturing

Change is happening at an increasingly rapid pace, and competition is one of the driving factors that forces organizations to respond to change and rethink strategies.

Chalk it up to the internet, increasing globalization, technology – you name it – there’s hardly an industry that’s not overcrowded, likely filled with a few thousand-pound gorillas that overshadow dozens of competitors in a given space.

So to continue growing – revenue, workforce, market share – in these crowded industries, it’s essential to innovate and create efficiencies for your operation, because there’s no time to lose and no money to waste.

Innovative roller manufacturing processes help us because they help you beat the competition

We feel this pressure at Pierce every day, no doubt about it.

Just as our customers need to adapt and grow, we’ve taken the necessary measures to create efficiencies in our organization so that we can offer the greatest value to our partners and offer better services than our competitors.

By doing this, we enable the industries we serve to become more competitive because they’re paying less for their products, receiving them quicker and offering solutions with high first-time quality.

Industrial roller manufacturing is one key area that we’ve focused on creating a better process to deliver greater value to our customers (and to maximize efficiency for our shop).

Innovative and cost-saving processes to create industrial rollers

Pierce uses innovative techniques known as Inertia Friction Welding, and Cylindrical Roll Forming to reduce cycle time, and reduce waste in our manufacturing processes.

In this article, we’ll look at cylindrical roll forming and its distinct advantages over traditional processes.

Traditional methods of manufacturing industrial rollers typically involves a process like these:

- A roller manufacturing process that uses 3 pieces to create the roller starts with a tube or core, and pre-machined gudgeons, which are then welded or press-fit together and finished with more machining.

- The 1-piece core manufacturing process starts with a single, solid core that is machined down to create journals to the appropriate length. This creates an excessive amount of scrap that has been machined off the end of the rollers.

If we continued down the traditional paths of 1-piece roller manufacturing, our output would be a fraction of what we’re able to achieve today with more innovative methods.

With the traditional process of manufacturing industrial rollers, we would be putting at least double the amount of resources into machining rollers, creating more scrap and producing fewer parts.

In a traditional 1-piece process, the customer is severely limited in options, and typically end up with a roller that’s much heavier than the application calls for, leading to more energy consumption and a risk of short life-cycle due to the extra strain.

Talk with an Engineer at Pierce and Start Creating Efficiencies for Your Operation

Cylindrical roll forming is a more efficient option to create industrial rollers

Instead of using the traditional 3-piece or 1-piece core manufacturing processes, Pierce has adopted a technology that uses heat and rotation to efficiently create industrial rollers.

Cylindrical roll forming is a 1-piece forming process, in which a single tube’s ends are heated until malleable, and then formed to near-net shape with a minimum of final machining required.

One difference between this and the traditional 1-piece process is that manufacturers have greater flexibility in their design and it’s possible to have varying thickness of the walls.

This can help create lighter-weight rollers which put less strain on the overall system, require less energy to operate, and reduce costs of raw materials.

Another difference is that there’s no need to machine off a significant amount of metal, meaning the cost of the product will be significantly reduced because the finished roller is very close in weight and length to the raw material.

Here’s how it works:

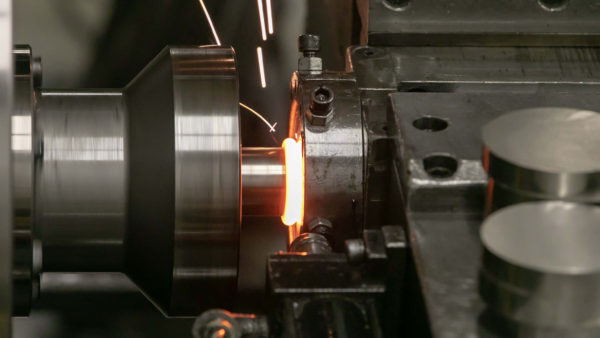

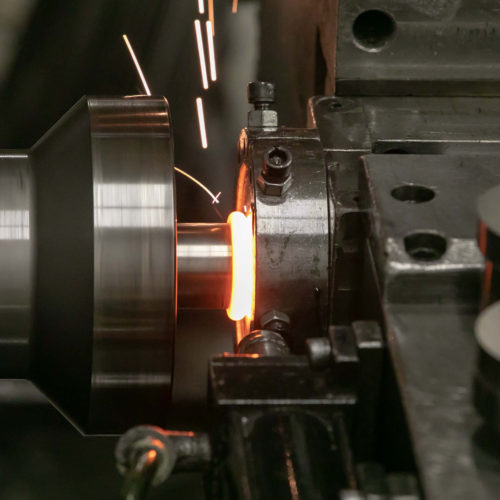

- The end of this single tube is laid over high-temp torches.

- The machine spins the tube rapidly which allows the torches to heat the entire end until it becomes red-hot and malleable.

- Once malleable, a pre-programmed CNC machine uses mandrels to form the end of the tube (picture a potter spinning and molding clay on a wheel) to the desired designed shape.

Creating an Industrial Roller: A single tube laid over high-temp torches becomes malleable for a CNC to form the end.

Creating an Industrial Roller: Cross-sections of rollers formed with the cylindrical roll forming process. Note the variable widths of the tube, different sizes and tapering.

When this process is finished, the rollers are very close to their final shape and will only require a minimal amount of machining to reach the exact designed dimensions.

The roll forming process makes efficient, reliable industrial rollers

Since this process is fully automated, it significantly reduces labor costs in our shop, which directly impacts the project cost for our customers.

Likewise, the ease with which we are able to produce a variety of wall thicknesses and shapes makes even diverse and complex projects manageable with less overall labor and time.

The labor savings continue through the end of the process because the cylindrical roll forming technique produces a shape that is so close to the final dimensions that minimal additional machining is required.

Where customers see the most savings from the roll forming process is in their material costs.

The goal of this process is to achieve a 1:1 ratio of purchased material weight and final product weight – meaning mostly everything you purchase is used to form the roller.

Since roll forming can produce industrial rollers out of one tube, manufacturers can expect significantly less scrap in each project.

The roll forming method can be performed on a variety of materials, including, but not limited to:

- aluminum

- copper

- steel

- stainless steel

- titanium

We’ve also seen customers in a wide range of industries benefit from the functionality and cost savings of industrial rollers formed with this process, including:

- Aerospace

- Agricultural

- Automotive

- Construction

- Converting Industry

- Defense

- Electrical

- Mining

- Office Equipment

- Oil & Gas

- Packaging & Conveyors

- Power Generation

- Renewable Energy

- Transportation

Overall, the efficiencies created by cylindrical roll forming create an opportunity to reduce material and production costs compared to traditional manufacturing methods.

By reducing the cost of your rollers, speeding up their cycle time and improving first-time quality, you will be able to offer extreme value to your customers while providing rollers that lead the industry in quality.

Get Started With an Engineering Consultation

Related Posts

How Pierce Industries Introduced Disruptive Technology to the Market What is Disruptive Technology? One of the more dangerous sayings in business is “but this is the way we’ve always done it.” Manufacturing and machining have been around for a long…

At Pierce Industries, we are proud to use the most innovative manufacturing processes to create custom designed parts and products for our clients. One of the more cutting-edge techniques that we use is Inertia Friction Welding. The process is very…

The manufacturing industry isn’t showing signs of slowing down. A recent look at the U.S. consumption of cutting tools shows a 10% increase year-to-date, along with an increase in machine tool orders. [Source] There are growing demands in industries that…

We specialize in providing custom manufacturing solutions to our Customers. Our overall goal is to reduce production time and material cost to increase competitiveness in the marketplace.

Latest Resources

Request More Information

© 2024 Pierce Industries. All rights reserved.