Industrial Steel Rollers Guide

In the world of industrial roller manufacturing and assemblies, how do you choose the right roller for your application?

When choosing or designing an industrial roller you’ll want to take into consideration requirements such as: typical speed; temperatures; load weight; driven or idler roller; environment (i.e. moisture and humidity levels); quantity; and finally, the material used.

Commonly used materials for industrial rollers include steel, aluminum, PVC, rubber, polyurethane, or some combination thereof. However, in this guide, we’ll be taking a close look at steel rollers.

Talk to Pierce about designs and manufacturing more effective industrial rollers.

Why choose steel rollers?

Steel rollers are often chosen for their durability, plain and simple. In an industrial setting, rollers are going to be subjected to a lot of wear and tear. On the Rockwell B Scale (used here for comparison purposes with aluminum), steel ranges in the 65 to 100 range, whereas aluminum measures in at 60. The higher the number on the Rockwell Scale, the harder the material. This means that steel will hold up longer than aluminum, leading to reduced replacements and maintenance costs. Not to mention keeping jobs on schedule instead of losing time when a conveyor system is shut down.

Steel is also preferred over aluminum in environments where the rollers will need to withstand higher temperatures (up to 350-degrees Fahrenheit).

Steel vs. plastic conveyor rollers

Advocates for plastic conveyor rollers tend to be in the food-based industries or processing plants where the equipment is subject to frequent washings and harsh chemical treatments as required by FDA and/or FSMA regulations. Untreated steel in these situations could corrode and require replacement.

It’s important to note, however, that in this particular application, stainless steel conveyor rollers are an oft-used alternative to plastic rollers. Stainless steel is easy to clean, resists corrosion and a popular choice for environments with strict hygiene conditions.

So in general, steel conveyor rollers significantly outperform plastic rollers in heavy industrial applications due to their durability.

Who is using steel rollers?

Steel rollers are most commonly used in conveyor systems, across a large reach of different industries, like mining and construction. Even in large scale shipping, packaging and distribution warehouses, manufacturing plants, or recycling facilities and small fabrication shops, conveyor rollers and systems are a necessity.

Steel rollers are also seen in roller and grinding mills as the density and strength of steel is useful in crushing ore, grain, plastics and softer rocks. A more exotic use of steel rollers can be seen in etching presses, where they are used in combination with plates to press prints into paper.

Steel roller components

Steel rollers and their components are manufactured around several specifications:

- Material: Plain steel, galvanized steel, stainless steel, zinc-plated steel or even an alloy of steel and aluminum

- Surface coatings: Coating the steel can lengthen its resistance to corrosion

- Type: Straight, concave, flanged or tapered

- Diameter of roller: Common sizes for conveyors range from ⅝” to 8”

- Load rating: What is the maximum capacity the rollers will need to hold?

- Tubing wall and thickness

Do steel rollers meet your need?

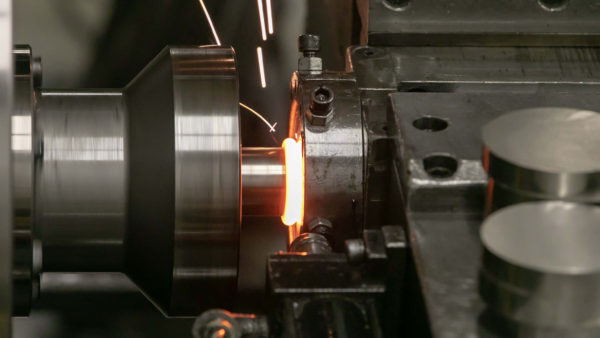

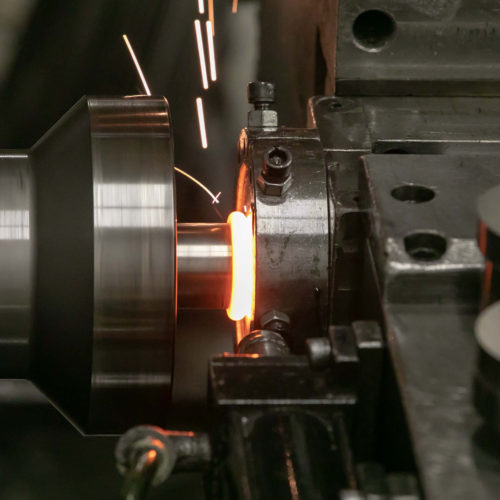

The manufacturing processes around industrial rollers have been changing, and for the better. Here at Pierce Industries, we’re pushing the innovation envelope and have embraced processes like cylindrical roll forming and inertia friction welding.

If you’re looking for a custom solution around steel rollers, contact us today for a consultation or quote.

Related Posts

How Pierce Industries Introduced Disruptive Technology to the Market What is Disruptive Technology? One of the more dangerous sayings in business is “but this is the way we’ve always done it.” Manufacturing and machining have been around for a long…

At Pierce Industries, we are proud to use the most innovative manufacturing processes to create custom designed parts and products for our clients. One of the more cutting-edge techniques that we use is Inertia Friction Welding. The process is very…

The manufacturing industry isn’t showing signs of slowing down. A recent look at the U.S. consumption of cutting tools shows a 10% increase year-to-date, along with an increase in machine tool orders. [Source] There are growing demands in industries that…