Industrial Roller Manufacturing

Manufacturing Industrial Rollers

Pierce Industries works with OEMs to design and manufacture industrial rollers. Using innovative methods – Inertia Friction Welding and Cylindrical Roll Forming – we help OEMs reduce material costs and improve roller quality.

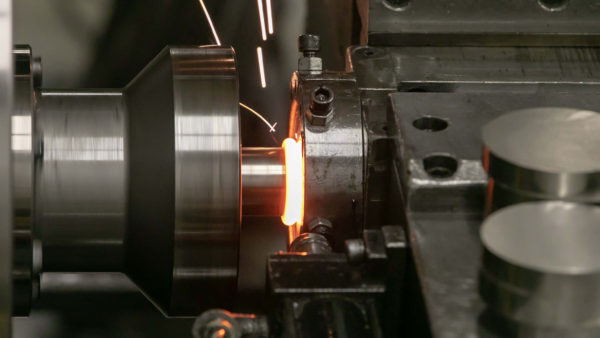

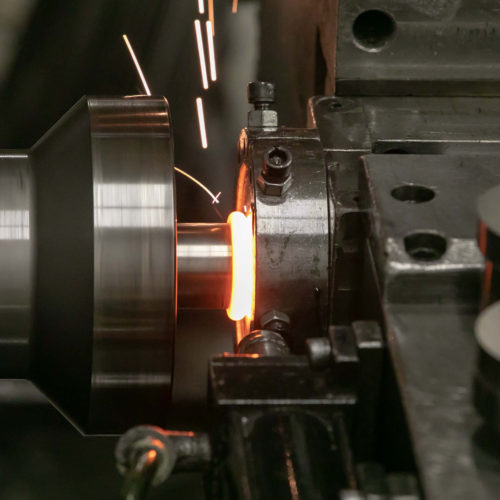

Inertia Friction Welding

IFW enables us to design and manufacture rollers in ways that traditional machining processes cannot.

This roller – made of aluminum and copper – was formed with the IFW process. One piece rotates, and then the two are pressed together, heating and plasticizing the metals, forging a perfect bond. CNC machining finishes to the roller you see.

Cylindrical Roll Forming

We manufacture more of your rollers in less time – while using less material – with the cylindrical roll forming process.

The image shows a cross section of rollers formed with this process. A tube is rotated and heated, then formed with CNC mandrels to achieve near net shape. Then machine finished to the form you see here.

CNC Machining

CNC Machining is often a part of the early stages and finishing processes in roller manufacturing. Our shop is equipped with 19 CNC machines, so you can benefit from a comprehensive, start-to-finish roller manufacturing process.

DESIGNING AND MANUFACTURING INDUSTRIAL ROLLERS FOR OEMS

- Digital Printing Equipment

- Packaging Equipment Manufacturers

- Photographic Printing Equipment

- Glass Equipment Manufacturers

- Mining

- Processing Equipment Manufacturers

- Converting Equipment Manufacturers

- Aerospace

- Transportation

We Specialize In Improving Industrial Rollers

The advantage of Pierce Industries is our capability to use a combination of methods to manufacture rollers that perfectly suit your application.

Tell our engineers what you need and let us improve your roller designs.

Get Started With Better Industrial Rollers

Talk with an engineer at Pierce about your rollers and applications, and let's work together to improve your current roller designs.

For us to run a typical roll journal type process, we are going to lose at least 50 percent of the material through the machining process. ... Two thirds of the billet will go from a 4 inch diameter to 2 inches or less, so you have a substantial amount of metal chips you are wasting.

Their process brings a significant reduction in material loss.