How Pierce Industries Introduced Disruptive Technology to the Market What is Disruptive Technology? One of the more dangerous sayings in business is “but this is the way we’ve always done it.” Manufacturing and machining have been around for a long…

At Pierce Industries, we are proud to use the most innovative manufacturing processes to create custom designed parts and products for our clients. One of the more cutting-edge techniques that we use is Inertia Friction Welding. The process is very…

The manufacturing industry isn’t showing signs of slowing down. A recent look at the U.S. consumption of cutting tools shows a 10% increase year-to-date, along with an increase in machine tool orders. [Source] There are growing demands in industries that…

In the world of industrial roller manufacturing and assemblies, how do you choose the right roller for your application? When choosing or designing an industrial roller you’ll want to take into consideration requirements such as: typical speed; temperatures; load weight;…

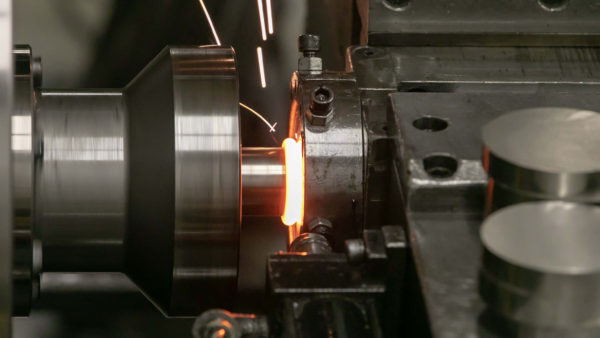

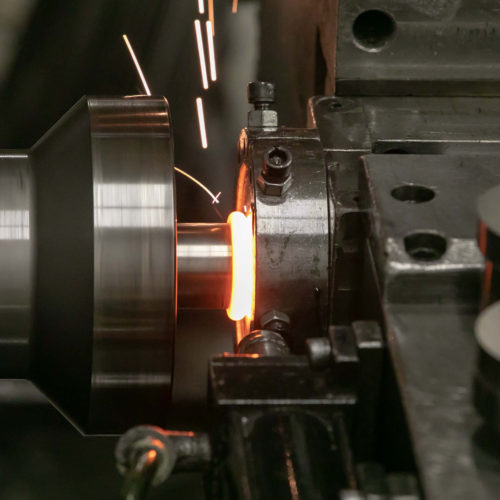

What is Inertia Friction Welding? Inertia friction welding is a solid-state welding process that joins materials by using rotation and friction to generate heat, and lateral force to plastically displace material and fuse the workpieces together. Since its early development,…

It wasn’t the strong that survived – it was the one who could respond and adapt to change. If we think about this in the business arena, it becomes even more apparent how adaptivity and responsiveness are paramount to surviving,…

There are many types of friction welding methods that can optimize your manufacturing process. In this article, we will review several different types. Understanding these different types will help you decide which can increase precision and reduce total cost and…

Manufacturing problems can hinder profitability for industrial printer and material handling OEMs. It is critical to be aware of these problems in your own manufacturing operations before they cost you your business. So what are the top manufacturing issues and…

Do you feel like your time, money, and management attention are tied up worrying about quality? One way to avoid buying low quality industrial rollers for your printing and material handling machines is to address friction welding quality control. Start…

In the current manufacturing environment, remanufacturing can positively impact a company’s bottom line. Breathing new life into a worn or damaged complex subassembly and reestablishing the performance it had when it was new can save a company a considerable amount…